信息來源于:互聯(lián)網(wǎng) 發(fā)布于:2021-08-16

Miele uses a In-Sight vision system from Cognex to ensure a long lifespan for the main spindles of the cable reels which are highly critical vacuum cleaner parts.

Position and Function

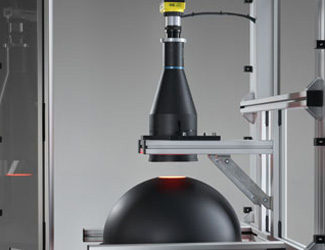

Vision systems integrator Weber Systemtechnik, perched the Cognex In-Sight® high above a large telecentric measuring lens with dome lighting. Underneath, white plastic components and tiny metal springs are fitted onto the black main carrier of the drum bearing. The correct positioning and dimensions determine whether the cable drum will work properly. The equipment here checks the completeness, precise positioning and the functional dimensions of the components after assembly.

Because the inspection requires absolute precision it is manually controlled. An operator puts the piece on the component carrier and rotates the transport plate through its four positions. The result can be seen not only in terms of the precision, but also in terms of the total number of components checked: up to 15,000 items go through the equipment every week. If a component passes inspection, it is moved on for further processing. If a fault is found in a drum bearing, the staff member removes it and enters the fault in a list. The defects identified by the In-Sight vision system have been categorized by Weber Systemtechnik into various coded classes. If required, the images of the defective parts can be stored so that they can be evaluated in detail at a later time.

Intelligent instruments create a flexible total solution

Twelve measurement points are used for checking the components in a process that’s only possible with machine vision. The metal spring tips of the part peep out of the plastic components by just a few tenths of a millimeter. But it is precisely these tiny parts that the In-Sight vision system records. One of its key instruments for this is image analysis using the PatMax® vision tool. PatMax applies sophisticated techniques for geometric pattern matching so that parts can be localized reliably and accurately. This technology allows the geometry of an object to be detected using a multiple boundary curves that are not bound to any pixel grid. PatMax looks for similar shapes in the image, without having to base it on specific grayscale values.

The VisionView® visualization option from Cognex handles the visualization and In-Sight Explorer provides fast and reliable parameterization. It makes highly flexible and extremely efficient configurations of vision tools possible. It also makes it easy to manage data acquired from an image processing application. Drag-and-Drop vision tools and a range of graphical tools with menu-driven tables for the tool properties simplify the process of configuring the tasks.